Electrodialysis wastewater treatment technology

Electrodialysis wastewater treatment technology Specification

- Treatment Method

- Electrodialysis Membrane Separation

- Control System

- PLC-Based Control with Monitoring

- Feed Water TDS Range

- up to 40,000 ppm

- Cleaning Method

- CIP (Clean-in-Place) Supported

- Installation Type

- Skid Mounted / Containerized

- Application

- Industrial and Municipal Wastewater Treatment

- Automation Grade

- Automatic / Semi-Automatic

- Voltage Range

- 20-60 V (depending on application)

- Type

- Electrodialysis Wastewater Treatment Technology

- Flow Rate

- 1-100 m3/h (customizable)

- Frame Material

- Stainless Steel 304/316

- Material of Construction

- Corrosion Resistant Material (e.g. PVC, FRP)

- Service Life of Membrane

- 2-4 Years (Typical)

- pH Range of Feed

- 2-11

- Membrane Type

- Cation and Anion Exchange Membranes

- Operating Temperature

- 5°C - 45°C

- Power Consumption

- 2-5 kWh/m3

- System Configuration

- Modular & Compact Design

- Treatment Efficiency

- 90-98% (depends on feed quality)

Electrodialysis wastewater treatment technology Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Sample Available

- No

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Electrodialysis wastewater treatment technology

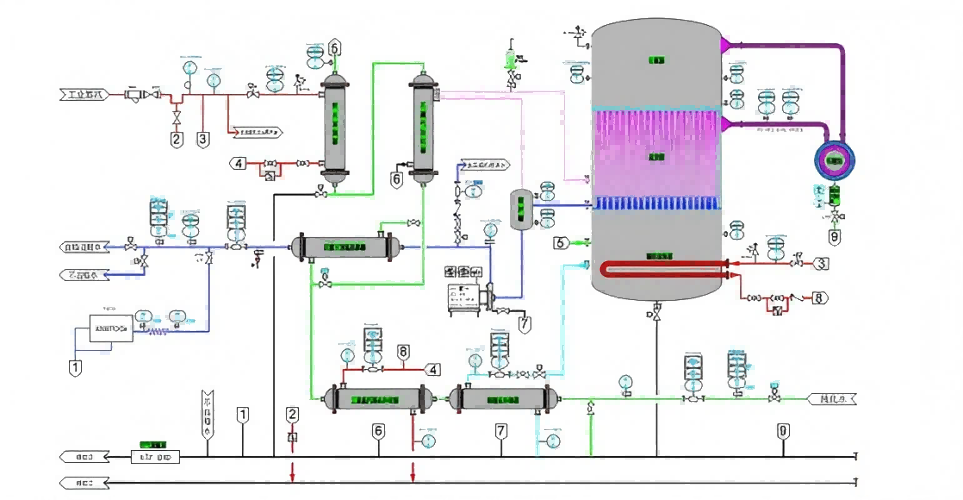

electrodialysis

Electrodialysis process is a combination of electrochemical process and dialysis diffusion process. Driven by the external direct current electric field, using the selective permeability of the ion exchange membrane (that is, the cation can pass through the cation exchange membrane, the anion can pass through the anion exchange membrane), the negative and the cation move to the anode and the cathode, respectively. In the process of ion migration, if the fixed charge of the membrane is opposite to the charge of the ion, the ion can pass through; If they have the same charge, the ions are repelled, thus achieving the purpose of solution desalination, concentration, refining or purification.

Wastewater treatment Applications:

-Acid waste water process to achieve efficient recovery of acids, valuable metals and water resources;

-Ammonium chloride wastewater treatment process to achieve efficient recovery of ammonium chloride and water resources;

-Electroplating wastewater treatment process, to achieve wastewater treatment and recycling or zero waste water discharge process;

-Zirconia production wastewater treatment and recycling;

-Zero discharge of catalyst production wastewater, raw water through sand filtration and ultrafiltration into the electrodialysis system, fresh water through reverse osmosis system to get workshop reuse water, concentrated water reached 20% into the evaporation system to achieve zero discharge;

-Rare earth industry wastewater treatment;

-Pharmaceutical industry wastewater treatment;

Advanced Modular Design

The electrodialysis system is designed with modular and compact features, offering versatile installation options such as skid-mounted or containerized setups. This ensures easy transportation and flexibility for varying site requirements, whether for large-scale municipal projects or smaller industrial facilities.

Efficient PLC-Based Control and Monitoring

An integrated PLC-based automation system guarantees precision control and continuous monitoring of operational parameters. This advanced interface enables seamless operation, quick diagnostics, and preventive maintenance, optimizing system efficiency and reliability.

CIP Cleaning and Durable Materials

The technology incorporates Clean-in-Place (CIP) cleaning, reducing system downtime and ensuring hygienic operation. Constructed from corrosion-resistant materials such as stainless steel 304/316, PVC, and FRP, the unit withstands harsh wastewater environments, ensuring a long service life and reduced maintenance demands.

FAQ's of Electrodialysis wastewater treatment technology:

Q: How does electrodialysis technology separate impurities from wastewater?

A: Electrodialysis employs cation and anion exchange membranes to selectively remove dissolved salts and contaminants from wastewater by applying an electrical potential, resulting in effective purification for both industrial and municipal applications.Q: What are the typical settings where this electrodialysis system can be installed?

A: The system is suitable for various settings, including industrial factories and municipal wastewater treatment plants. Thanks to its modular, skid-mounted, or containerized design, it is adaptable to different site requirements and operational scales.Q: When should membrane maintenance or replacement be performed?

A: Membrane maintenance should be conducted routinely, with replacements typically recommended every 2 to 4 years based on feed water quality and system usage. Clean-in-Place (CIP) cleaning extends membrane lifespan and maintains optimal performance.Q: What range of feed water TDS and pH can the system accommodate?

A: This electrodialysis technology treats feed water with TDS levels up to 40,000 ppm and a pH range from 2 to 11, making it highly effective for diverse wastewater profiles encountered in industrial and municipal processes.Q: Where can this technology be exported or supplied from?

A: As a distributor, exporter, manufacturer, supplier, and trader based in China, this technology is available for global distribution, catering to a broad market for wastewater treatment solutions worldwide.Q: How does automation benefit the operation of this electrodialysis system?

A: The automatic or semi-automatic PLC-controlled operation streamlines the treatment process, reduces manual intervention, enhances monitoring, and guarantees consistent and efficient results, leading to improved productivity and water quality.Q: What is the expected treatment efficiency and power consumption of the system?

A: Treatment efficiency ranges from 90% to 98% depending on the feed quality, while power consumption typically falls between 2 to 5 kWh per cubic meter, resulting in cost-effective and energy-efficient wastewater management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Technology Category

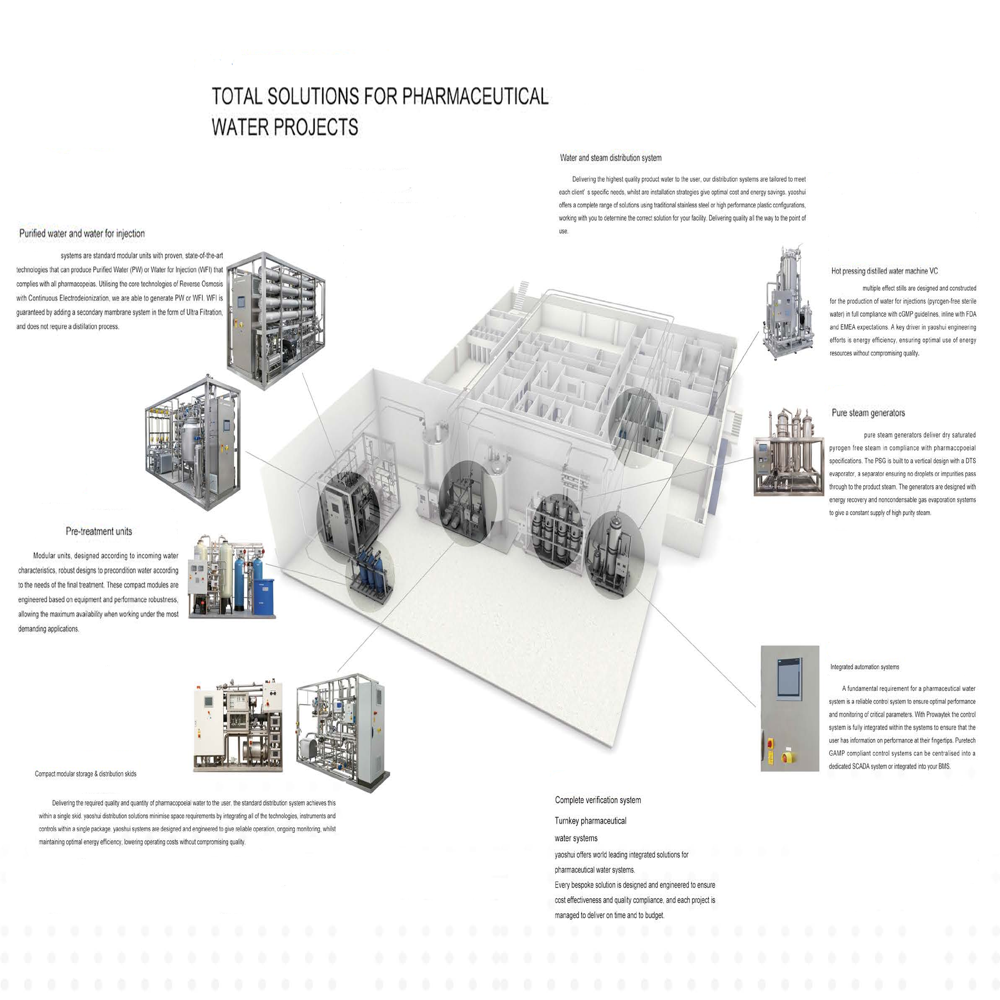

Pharmaceutical use and water integration system

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Production process and technology of distilled water and pure water

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste alkali recovery technology

Price 5000.0 USD ($)

Minimum Order Quantity : 1

Combined technique of nanofiltration and electrodialysis NF-ED

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free