Production process and technology of distilled water and pure water

10000.0 USD ($)/Unit

Product Details:

X

Production process and technology of distilled water and pure water Price And Quantity

- 1 Unit

- 10000.0 USD ($)/Unit

Production process and technology of distilled water and pure water Trade Information

- Telegraphic Transfer (T/T) Letter of Credit (L/C)

- 1 Unit Per Day

- 2 Months

- No

- North America South America Eastern Europe Asia Australia Central America Western Europe Middle East Africa

- All India

Product Description

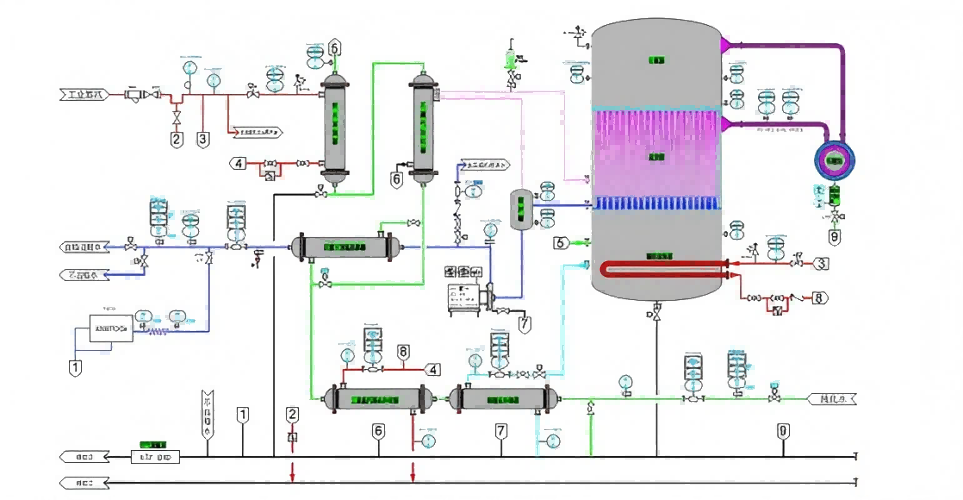

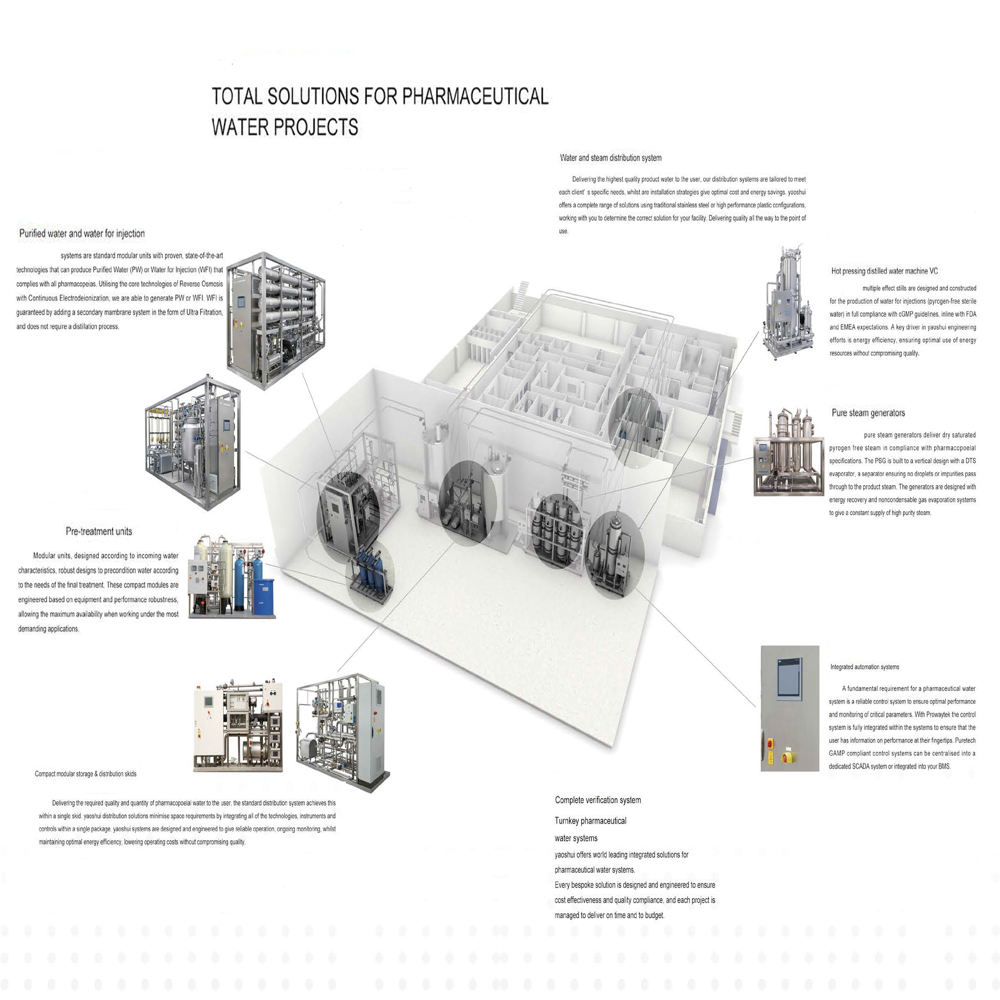

Purified water is heated and evaporated in the tube of a vertical tubular up-film evaporator, and the new steam generated rises and is separated by a high-efficiency vapors and liquids separator. The new steam separated becomes saturated pure steam (also known as dry saturated steam), and the saturated pure steam is pressurized to increase the temperature and enthalpy after being sucked in by the hot compressor, and then sent to the shell of the evaporator by the hot press. The purified water of the pipe is heated and evaporated, and the distilled water itself is condensed into distilled water and flows out of the evaporator, and is sent to the injection water storage tank by the pump for reserve. The purified water that has not been evaporated flows to the bottom from the central pipe of the evaporator, and a small part of it is discharged out of the evaporator as concentrated water and thrown away after cooling, and most of it is mixed with the newly added purified water and then heated to evaporate.

Process description: The purified water is successively sent into the concentrated water cooler, the industrial steam condensate cooler, the distilled water temperature control heat exchanger, the non-condensing gas cooling heat exchanger, and the feedwater heater after heating into the evaporator to be heated and evaporated.

The core technology of hot pressing distilled water machine is to use a steam compressor to pressurize pure steam, thereby increasing the temperature and enthalpy of pure steam, and then using the pure steam after increasing the temperature and enthalpy value to heat and evaporate the purified water in the pipe. The hot press converts electrical energy into compression work, and then converts the compression work into heat energy for evaporation operation, that is to say, electricity is converted into heat energy for evaporation operation to produce distilled water.

The main working energy consumption of the hot press distilled water machine is that the boiler steam is used for heating the material water and the compressor is used for evaporation operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry