Diffusion dialysis and electrodialysis combined technology

Diffusion dialysis and electrodialysis combined technology Specification

- Technology Type

- Diffusion Dialysis and Electrodialysis Combined

- Process Sequence

- Diffusion dialysis unit followed by electrodialysis unit

- Feed Solution

- Industrial waste liquids, acid/alkali solutions

- Membrane Type

- Anion exchange membranes (AEM), cation exchange membranes (CEM)

- Application

- Separation and recovery of acids, alkalis, and salts

Diffusion dialysis and electrodialysis combined technology Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Sample Available

- No

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Diffusion dialysis and electrodialysis combined technology

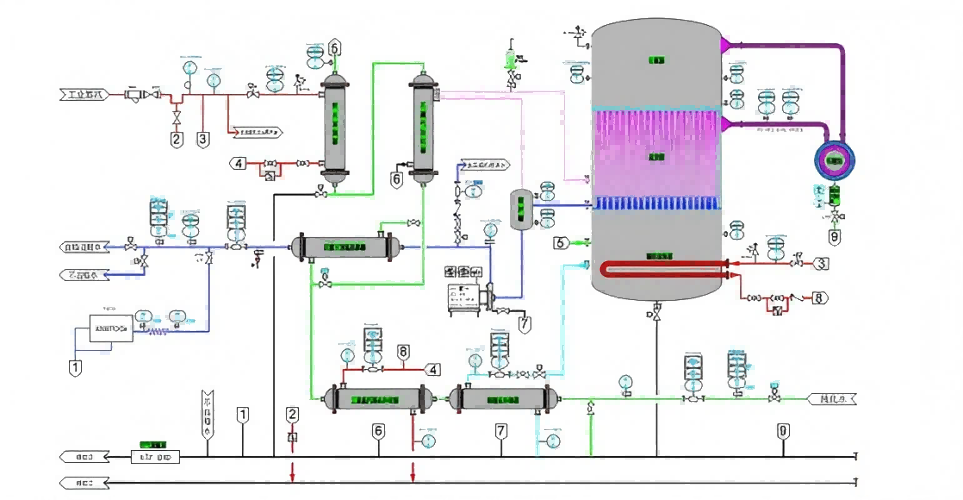

Through the joint application of diffusion dialysis and electrodialysis, the production of raw materials can be fully utilized, the output of waste water can be reduced, and the sustainable water can be realized through reuse.

Step1

The extraction mother liquor (containing 10% hydrochloric acid) enters the diffusion dialysis system for the separation of hydrochloric acid and organic acid after removing solid impurities through a security filter;

Step2

Recovered hydrochloric acid with a high concentration of hydrochloric acid and almost no organic acid is reused;

Step3

The obtained hydrochloric acid concentration is less than 2% and the residual liquid containing high organic acid enters into the electrodialysis system for the deep separation and recovery of hydrochloric acid, and the residual liquid containing high organic acid enters into the electrodialysis system;

Step4

Concentrated water with a hydrochloric acid concentration of less than 0.1% and a high organic acid concentration is used in the product crystallization process.

Innovative Two-Stage Membrane Separation

This technology combines diffusion dialysis and electrodialysis in a sequential setup, maximizing recovery rates of acids and alkalis from industrial effluents. The diffusion dialysis unit first separates acids or alkalis using selective membranes, while the following electrodialysis stage further refines and concentrates the recovered chemicals. This dual approach ensures greater purity and reduces operational costs.

Sustainable Waste Management Solution

By applying anion and cation exchange membranes, the system enables sustainable treatment of waste liquids, minimizing environmental impact. The recovered acids and alkalis can then be reintroduced into industrial processes, which not only conserves resources but also cuts waste disposal expenses. This makes the technology highly relevant for environmentally conscious industries across India.

FAQ's of Diffusion dialysis and electrodialysis combined technology:

Q: How does the combined diffusion dialysis and electrodialysis technology work?

A: The process begins with diffusion dialysis, where anion exchange membranes (AEM) selectively separate acids or alkalis from industrial waste liquids. The resulting solution is then fed into an electrodialysis unit, where cation exchange membranes (CEM) and AEMs further separate and purify the acids, alkalis, and salts for recovery.Q: What are the main applications of this technology?

A: It is primarily used for the separation and recovery of acids, alkalis, and salts from industrial process solutions, especially in industries generating large amounts of acidic or alkaline waste, such as chemical manufacturing, metal finishing, and wastewater treatment.Q: When is it appropriate to use this combined membrane technology?

A: This technology is well-suited when industries need to treat waste streams containing recoverable acids or alkalis, reduce discharge pollutants, and recycle chemicals to enhance resource efficiency and comply with environmental regulations.Q: Where can this system be implemented in India?

A: It can be installed at industrial facilities, wastewater treatment plants, and manufacturing sites across India that handle or generate acid or alkali solutions, and is available through distributors, exporters, manufacturers, suppliers, and traders nationwide.Q: What types of feed solutions are compatible with the system?

A: The system is compatible with various industrial waste liquids, including spent acid or alkali solutions commonly found in chemical, textile, or metal processing industries.Q: What are the key benefits of using this technology?

A: The primary benefits include effective separation and high recovery rates of valuable acids, alkalis, and salts, reduced environmental footprint, decreased wastewater treatment costs, and the ability to reuse recovered chemicals in industrial processes.Q: How do the membrane types contribute to the process?

A: Anion exchange membranes (AEM) selectively transport anions, enabling acid recovery, while cation exchange membranes (CEM) selectively allow cations, facilitating alkali separation. This dual-membrane setup enhances the selectivity and efficiency of both recovery stages.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Technology Category

Production process and technology of distilled water and pure water

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste acid recovery technology

Price 1000.0 USD ($) / Plant

Minimum Order Quantity : 1 Plant

Diffusion dialysis - waste alkali recovery technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free