Diffusion dialysis - waste acid recovery technology

Product Details:

Diffusion dialysis - waste acid recovery technology Price And Quantity

- 1000.0 USD ($)

- 1

Diffusion dialysis - waste acid recovery technology Trade Information

- Telegraphic Transfer (T/T) Letter of Credit (L/C)

- No

- 1, good removal of organic matter in waste acid, special adsorption material adsorption capacity, high concentration ratio, low cost; 2, the waste acid after treatment can be recycled for production, to realize the resource utilization of waste acid; 3, waste acid recovery and treatment equipment covers an area of saving, compact structure, less civil construction and equipment costs, multiple application of desorption agent, step by step enrichment, high utilization rate of agents, low operating costs; 4, can achieve module component form, can be flexibly adjusted according to production capacity, easy to install; 5, waste acid recovery process is good, mature, strong technical support and rich experience in engineering application. Engineering application: The technology has been widely used in foil formation, hydrometallurgy, chemical separation, iron and steel industry, non-ferrous metal processing and other etching industries, which not only solves the problem of environmental pollution for enterprises, but also recovers the acid in the acid waste liquid for recycling and utilization, with significant economic and social benefits.

- Asia Australia South America Eastern Europe Western Europe Middle East Africa Central America North America

- All India

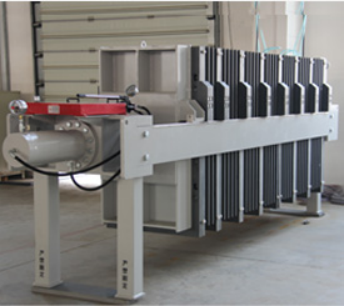

- The whole device is a series of structural units composed of a certain number of membranes. Each unit is separated by an anionic homogeneous membrane into a dialysis chamber and a diffusion chamber. Countercurrent operation is adopted. When the spent acid solution and the receiving solution (tap water) are passed into both sides of the anionic homogeneous membrane, the concentration of acid and its salts on the spent acid solution side is much higher than that on the water side. However, the membrane has selective permeability to anions, so under the action of the concentration difference, the anions on the waste acid side are attracted and enter the water side smoothly through the membrane pores. At the same time, according to the requirements of electric neutrality, cations will also be included, because the hydration radius of H+ is relatively small, and the charge is less; The hydration radius of metal salts is larger and the charge is more, so H+ will preferentially pass through the membrane, so that the acid in the waste liquid will be separated.

Product Description

Diffusion dialysis method (ionic membrane method) to recover waste acid adopts the principle of dialysis, which is driven by concentration difference. This product membrane and its equipment are mainly used for the separation and purification of the mixed liquid of acid and metal salts, which is a good choice in the field of waste acid. It has the advantages of simple operation, saving energy and resources, no secondary pollution, etc. The recovered acid can be recycled, and the residual liquid after separating acid can recover useful metals. It is widely used in various fields of discharge of waste acid: such as iron and steel industry, titanium dioxide industry, wet smelting of copper industry, electroplating industry, formation, rare earth industry and other non-ferrous metal smelting industry, the types of recovered acid can include sulfuric acid, hydrochloric acid, HF, nitric acid, etc., the metal ions involved mainly include transition metal ions, rare earth ions and magnesium calcium and so on. The recovery rate of acid can reach more than 80%, and the removal rate of metal ions can reach more than 90%.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Call Me Free

Call Me Free